We see a variety of food packaging bags emerging in the market, mainly food packaging bags. For ordinary people, they may not even understand why a food packaging bag needs so many types. In fact, in the packaging industry, according to the type of bag, they are also divided into many bag types. Today, I will take you to understand the types of food packaging bags, so that you can eat with peace of mind!

Three sided sealing bag: As the name suggests, it means three sided sealing, leaving an opening to hold the product. It is a common type of food packaging bag. The three sided sealing bag has two side seams and one top seam. This type of packaging bag can be folded or not, and can stand upright on the shelf when folded.

Back sealing bag: A back sealing bag is a type of packaging bag that is sealed on the back edge of the bag. This type of bag has no opening and requires manual tearing. It is often used for small sachets, candies, dairy products etc.

Four sided sealing bag refers to the packaging form in which all four sides of the bag are heat sealed after being formed. Usually, a whole packaging film is divided into two halves for relative packaging. The overall heat sealing is used and then cut into a single bag. During production, controlling the alignment of one side edge can achieve good packaging effect. After packaging the product with four sided sealing bags, it forms a cube and has a good packaging effect.

Eight sided sealing bag/Flat bottom pouch: This is a bag type developed on the basis of a self-supporting bag, which can also be upright due to its square bottom. This bag shape is more three-dimensional, with three flat surfaces: front, side, and bottom. Compared to self-standing bags, octagonal sealed bags have more printing space and product display, which can better attract consumer attention.

Stand up zipper bag: Self standing zipper bag, which adds an openable zipper above the packaging for easy storage and use, avoiding moisture. This type of bag has good flexibility, moisture-proof and waterproof properties, and is not easily damaged. The nozzle bag is composed of two parts, with an independent nozzle on the top and a self-supporting bag on the bottom. This type of bag is the first choice for packing liquid, powder and other products, such as juice, beverage, milk, soybean milk etc.

Automatic packaging roll film: The main advantage of using roll film in the packaging industry is to save the cost of the entire packaging process. Roll film is used in automatic packaging machinery, without the need for packaging production enterprises to perform any edge sealing, only one-time edge sealing is required in production. Roll film packaging is fully electric and integrated, and the machinery can package itself, which can save manpower and financial resources.

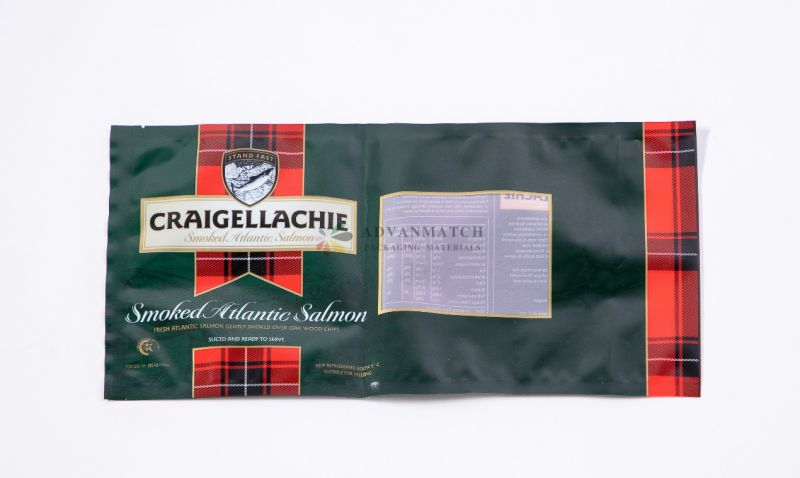

Qingdao Advanmatch Packaging specialize in providing one-stop customized packaging services for plastic flexible packaging, packaging film rolls, food packaging bags, vacuum packaging bags, boiled packaging bags, aluminum foil packaging bags, daily chemical packaging bags, medical packaging bags, etc. We have 21 years of production experience in customizing various bag types and styles of packaging bags, and tens of thousands of customers choose to trust Qingdao Advanmatch Packaging Factory not only because we provide one-stop services, but also because we have rich production experience.

Post time: Apr-09-2024