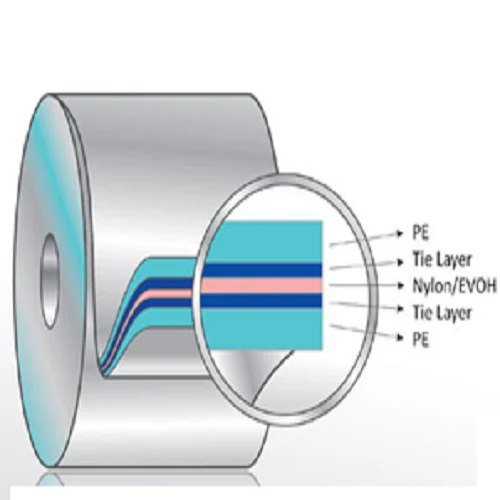

The structures of multilayer co-extruded films can be divided into two categories, namely symmetric structure (A/B/A) and asymmetric structure (A/B/C). At present, the barrier films in China are mainly composed of 5 layers, 7 layers, 8 layers and 9 layers. The symmetrical structural layer of multilayer co-extrusion barrier diaphragm is composed of three types of functional layers, namely barrier layer, adhesive layer and support layer.

Barrier layer: the barrier layer has the functions of oxygen resistance, moisture resistance and oil leakage prevention. Through the control of barrier layer materials and thickness, the barrier performance of film materials can be adjusted to meet different packaging needs (barrier materials commonly used in the market include PA, EVOH, PVDC, etc.

Supporting layer: generally, symmetrical structural materials have two supporting layers. The inner layer is used for heat sealing, which is a heat-sealing layer, while the outer layer is directly used as the outer layer or printing layer of the packaging film. The support layer shall have good mechanical strength, heat sealing performance, water vapor resistance, transparency and printability. The common materials of this layer are LDPE or LDPE/LLDPE blend materials.

Bonding layer: the role of the bonding layer is to bond the barrier layer and the support layer to ensure the peeling force between layers. The selection of the bonding layer material and thickness usually depends on the materials of the support layer and the barrier layer and the required bonding strength to determine the adhesive material used for the bonding layer.

At the same time, the thickness of each layer can be adjusted through the extrusion process. By adjusting the thickness of the barrier layer and the proportion of raw materials, the film with different barrier properties can be flexibly produced. The heat-sealing layer materials can also be replaced and adjusted to meet the needs of different packaging. The multilayer and multi-functional co-extrusion composite is the mainstream direction of the development of packaging film materials in the future.

In order to extend the shelf life of current food and drug packaging, many packaging materials use multilayer co-extruded composite films. In application, it fully demonstrates the excellent characteristics of quality assurance, cold storage, taste protection, long shelf life, acid and alkali resistance, moisture and cold resistance, heat resistance, low temperature and cold storage resistance, and very high strength.

Post time: Apr-03-2023