Paper box packaging is largely used to promote and beautify products and enhance their competitiveness through its exquisite design and decoration. Due to the fact that the shape and structural design of paper boxes are often determined by the shape characteristics of the packaged goods, there are many styles and types, including rectangular, square, multilateral, irregular paper boxes, cylindrical etc., but their manufacturing process is basically the same.

This article shares the classification, common structures, and production techniques of paper gift boxes, for friends to refer to:

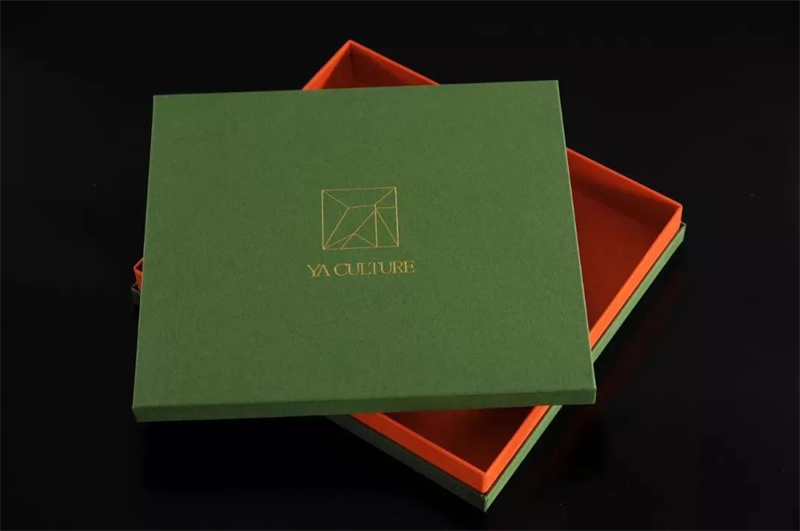

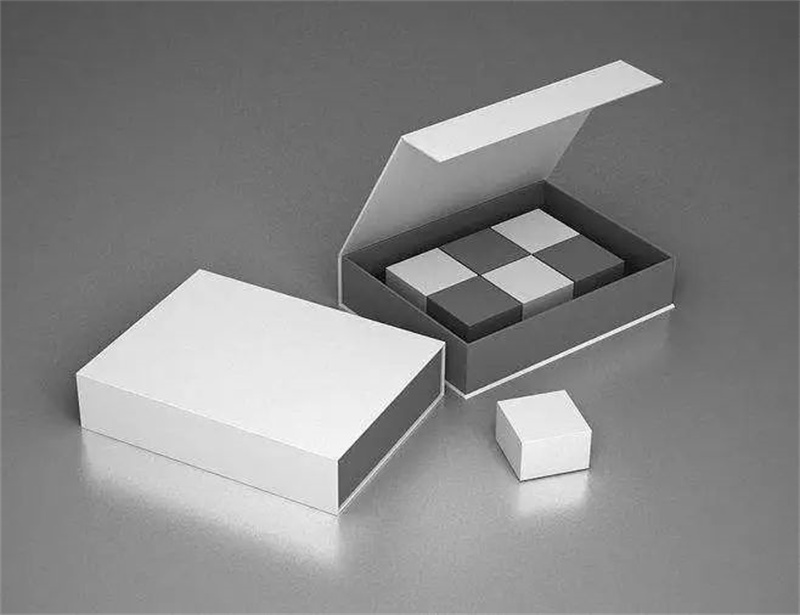

A paperboard or cardboard box is a three-dimensional shape composed of multiple faces that move, stack, fold, and surround each other. The faces in three-dimensional composition play a role in dividing space. By cutting, rotating, and folding different parts of the faces, the resulting faces have different emotional expressions. The composition relationship of the cardboard box display surface should pay attention to the connection relationship between the display surface, side, top and bottom, as well as the setting of packaging information elements.

Carton design is still an abstract form of language expression. The shape of paper boxes can be explored and created from the perspectives of vitality, dynamism, volume, depth, and other aspects. At the same time, combining the principles of form beauty such as unity, contrast, proportion, fusion, change and unity, and dynamism, we aim to create a dynamic and interesting shape for paper box packaging.

The paper box packaging structure should fully utilize the forming characteristics of polyhedra in terms of the functions and characteristics of goods, and cleverly use body language to express the characteristics of goods and the beauty of packaging. In fact, the structure of a paper box is not only about creating a three-dimensional rendering of the box, but also involves the production process, including the plane structure diagram of the paper box, knife mold production, and box pasting molding. These links should be fully considered during design. This requires designers to have a considerable understanding of the structural process of paper boxes, so that the design can be put into production.

1. Common Classification of Paper Boxes

Divided by laminating fabric

Paper: including gold and silver cardboard, pearl paper, and various types of art paper etc.

Leather material: including genuine leather, simulated leather PU fabric etc.

Fabric: including various cotton and linen texture fabrics etc.

Divided by application scope

Daily chemicals: mainly used in cosmetics, perfume etc.

Liquor: mainly used in Baijiu, red wine and various foreign wines

Food category: used on any kinds of foods and seafood

Tobacco: mainly used in high-end premium cigarettes

Digital electronics: mainly used in mobile phones, tablets etc.

Jewelry category: mainly used for various types of jewelry

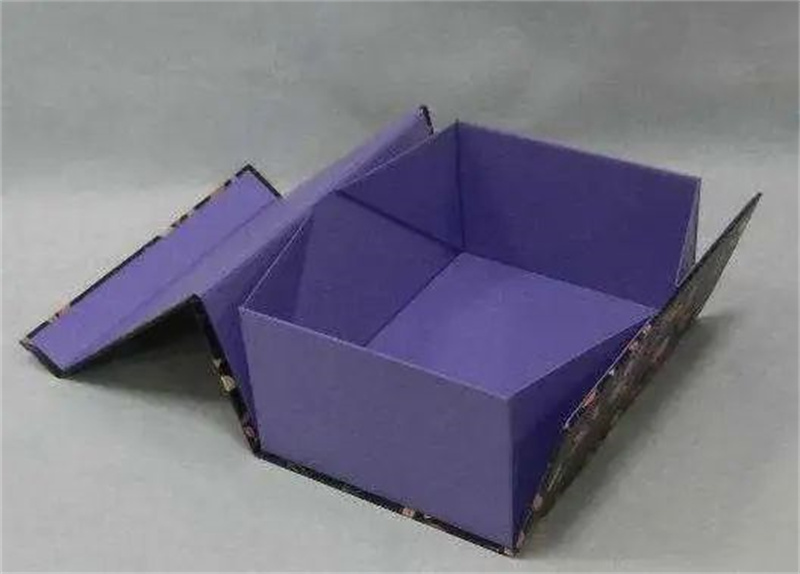

2. Common structures of paper boxes

Full Telescope Design Style Container (FTD)

Roll end tuck top (RETT)

Roll End Tray with Locking Cover

Heart-shaped box

Drawer box

Round shaped box

Hexagonal/octagonal/polygonal box

Clear window box

Folding box

Post time: Jul-11-2023