First of all, the multilayer co-extrusion resistance diaphragm is a plastic film. In the field of plastic products, we usually refer to flat plastic products with thickness less than 0.2 mm as plastic films, those with thickness between 0.2 and 0.7 mm as plastic sheets and those with thickness greater than 0.7 mm as plates. Multilayer co-extrusion resistance diaphragm shall have certain gas barrier performance. The barrier here refers to the shielding ability of plastic products (containers, films) against small molecular gases and odors. We usually use the gas permeability to measure the permeability of plastic products. PE, PP and other general plastics have large gas permeability values, that is, the gas permeability is poor, while PA, PVDC, EVOH and other resin materials have much lower gas permeability values than general plastics, and the gas permeability is good. Therefore, we usually call the multilayer coextrusion film containing at least one resin material of PA, PVDC and EVOH as the multilayer coextrusion resistance diaphragm. PE, PA, TIE, EVOH and other resins can be used for vacuum packaging of dairy products, jam, meat products, etc.

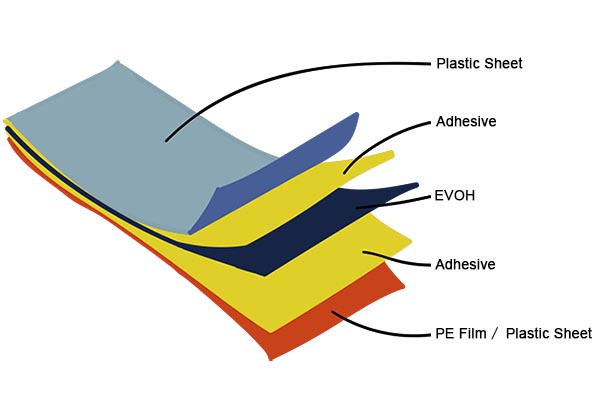

Multilayer co-extruded films mostly adopt ABCBA5 layer symmetrical structure, with PA or EVOH as barrier layer and polyethylene as thermal seal layer. The adhesive resin is used to separate the unconnected barrier layer and thermal seal layer. PA or EVOH is extremely sensitive to humidity, protected by polyethylene layer, and its excellent oxygen barrier performance has been fully developed. In general, the structure of multilayer co-extruded film depends on the functional requirements of the film. On the premise of meeting the process requirements, the combination of different polymers can meet the functional requirements of packaging materials such as barrier, heat sealing, body strength, thermal puncture, environmental adaptability, secondary processing characteristics and extension of storage and shelf life. From the perspective of functional requirements, the combination of five polymers is sufficient. However, the co-extruded composite film with seven, nine, eleven or more layers has been applied in the market that making it a trend and developing rapidly. The structural design of co-extruded film is gradually required to achieve the ideal state of integrating function, technology, cost, environmental protection, safety and secondary processing.

1. Cost comparison

Using cheaper polymers on the surface instead of expensive polymers can reduce the cost of products and has the heat-sealing performance and high moisture resistance of ionic chain polymers. For materials with the same barrier and heat-seal-ability 7-layer co-extrusion blown film is more economical than 5-layer film.

2. Barrier

Using two different polymers instead of a single polymer on the barrier layer can greatly improve its barrier property. For example, the combination of EVOH layer and typical nylon material can not only maintain the penetrability of PA, but also increase the strength of EVOH and improve the crack resistance of EVOH because the EVOH layer is sandwiched between two layers of PA amine, making it a film with high barrier, while the five-layer co-extrusion film can not be achieved. The increased cost of adding EVOH can be added to the total consumption of the structure. The oxygen transmission rate of the five-layer co-extruded film with 20% PA structure is 3.5 units, but under the same conditions, the transmission rate of EVOH added to the seven-layer film is 0.13 units.

3. Crack resistance

The properties of PA co-extruded films with more layers can be improved. For example, the use of additional adhesive layer can improve the barrier performance of the film by increasing the water vapor barrier effect of the film. Another advantage obtained at the same time is that it can make the film more soft, feel good and have good crack resistance.

With the continuous progress of polymer synthesis technology, new polymers with unique physical and mechanical properties can be widely used to meet the needs of packaging. The function and structure of multilayer co-extruded composite substrate film will have greater flexibility and economy. Through the application and improvement of molding equipment and technology, combined with the unique and effective design of composite structure, film manufacturers will have a revolutionary role in the pursuit and thinking mode of the concepts of diversification of packaging functions, rationalization of packaging structure, and maximization of packaging benefits.

Post time: Apr-17-2023