In the entire printing and packaging industry, color box packaging is a relatively complex category, as many things do not have standardized processes due to different designs, structures, shapes, and processes. Today, I have organized the structural design of common color box packaging single paper boxes, which are mainly divided into two parts: tube packaging boxes and disc packaging boxes.

Design of Tubular Packaging Structure

Tubular packaging boxes are the most common form of daily packaging, and most color box packaging such as food, medicine, and daily necessities use this packaging structure. Its characteristic is that during the forming process, both the box cover and the box bottom need to be folded and assembled (or bonded) to fix or seal, and most of them are in a single structure (the unfolded structure is a whole). There are adhesive ports on the side of the box body, and the basic form of the paper box is a quadrilateral, which can also be expanded into a polygon based on this. The difference in the structural characteristics of tube packaging boxes is mainly reflected in the assembly method of the lid and bottom. Below, we will take a look at the different lid and bottom structures of tube packaging boxes.

1.Cover structure of tube packaging box

The box cover is the entrance for storing goods and also the exit for consumers to retrieve them. Therefore, in terms of structural design, it is required to be easy to assemble and open, which not only protects the goods but also meets the opening requirements of specific packaging, such as multiple opening or one-time anti-counterfeiting opening methods. There are several main ways to structure the cover of a tube packaging box.

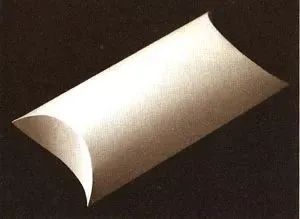

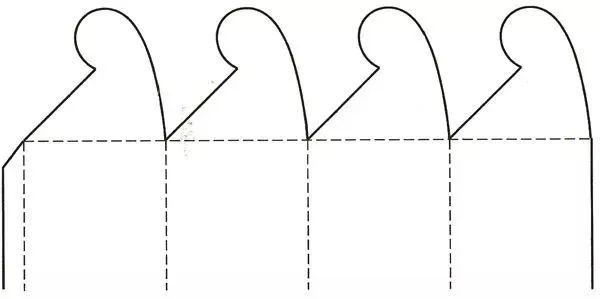

Insert swing cover type

The box cover has three swing cover parts, and the main cover has an extended tongue for insertion into the box body for sealing purposes. When designing, attention should be paid to the bite relationship of the swing cover. This type of cover is most widely used in tubular packaging boxes.

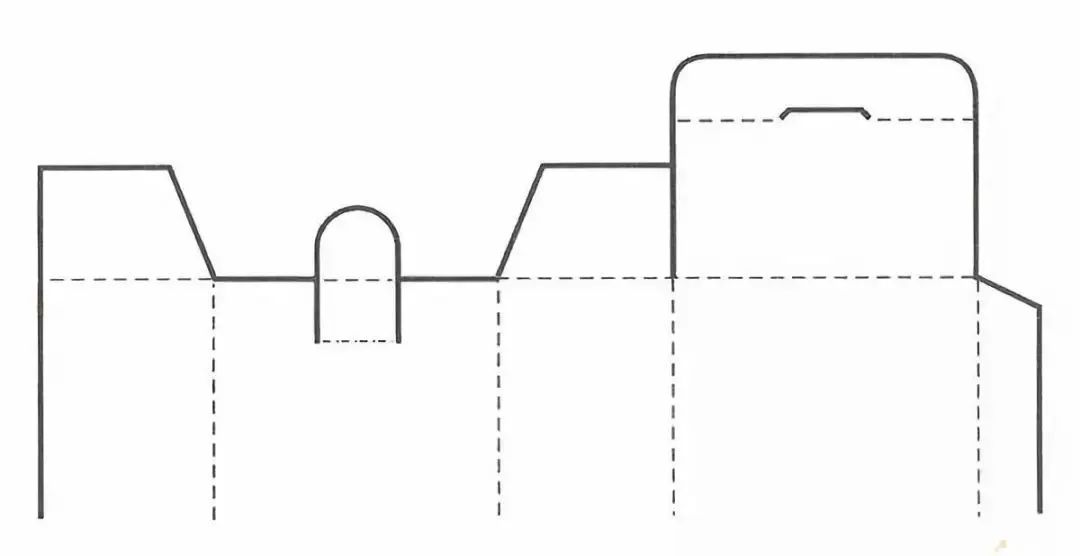

Expanded view of the structure of the inserted swing cover box cover

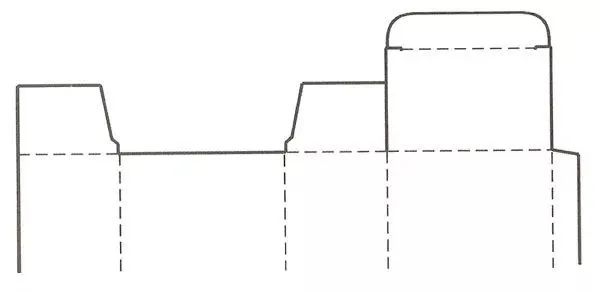

Locking type

This structure creates a connection and locking between the front and back swing covers, making the sealing more secure. However, assembly and opening are slightly cumbersome.

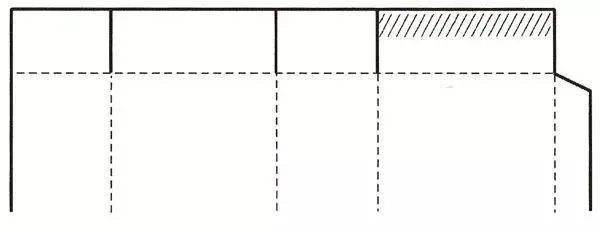

Unfolded diagram of lock type box cover structure

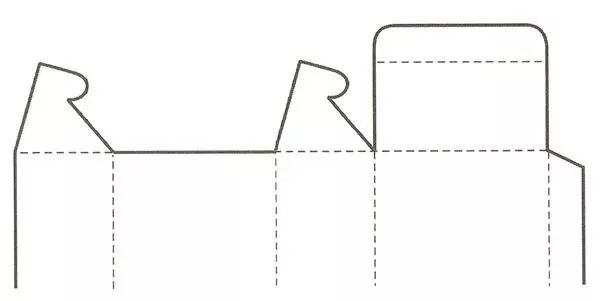

Latch type

A combination of insertion and locking, with a structure that is more secure than the insertion of a swing cover.

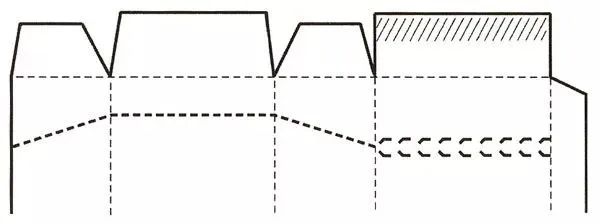

Expansion diagram of plug-in lock box cover structure

Swing cover double safety plug-in type

This structure makes the swing cover subject to double bite, which is very firm. Moreover, the bite between the swing cover and the cover tongue can be omitted, making it easier to open and use it multiple times.

Expansion diagram of the structure of the double fuse insertion box cover

Adhesive sealing type

This bonding method has good sealing performance and is suitable for automated machine production, but it cannot be opened repeatedly. Mainly suitable for packaging powdered and granular goods, such as laundry detergent, cereal, etc. Once opened, they cannot be reused.

Structural expansion diagram of adhesive sealing box cover

Disposable anti-counterfeiting type

The characteristic of this packaging structure form is the use of toothed cutting lines, which can damage the packaging structure while the consumer opens the packaging, preventing anyone from using the packaging again for counterfeit activities. This type of packaging box is mainly used in drug packaging and some small food packaging, such as film packaging/tissue paper packaging boxes, which are currently also opened in this way.

Deployment diagram of disposable anti-counterfeiting box cover structure

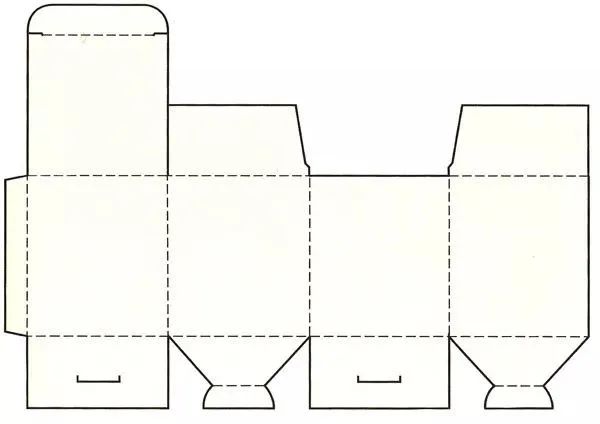

Positive press sealing type

By utilizing the folding resistance and toughness of paper, using curved folding lines and pressing the wings, sealing can be achieved. This structure is extremely convenient for assembly, opening, and use, and is the most paper saving and beautiful in shape, making it suitable for packaging small goods.

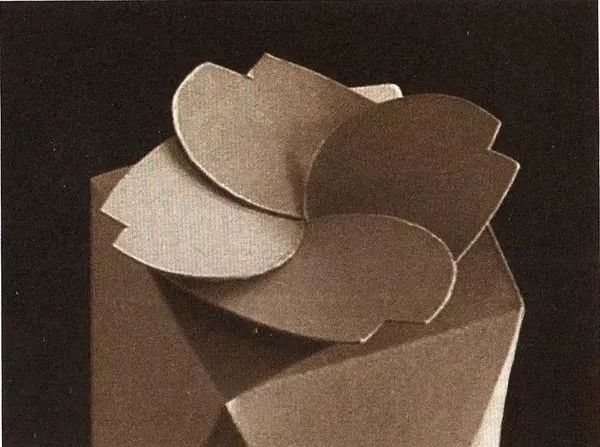

Continuous wing swing nest type

This locking packaging structure has a beautiful shape and is highly decorative, but manual assembly and opening are more troublesome, making it suitable for gift packaging, such as wedding candy packaging boxes and Christmas gift packaging boxes.

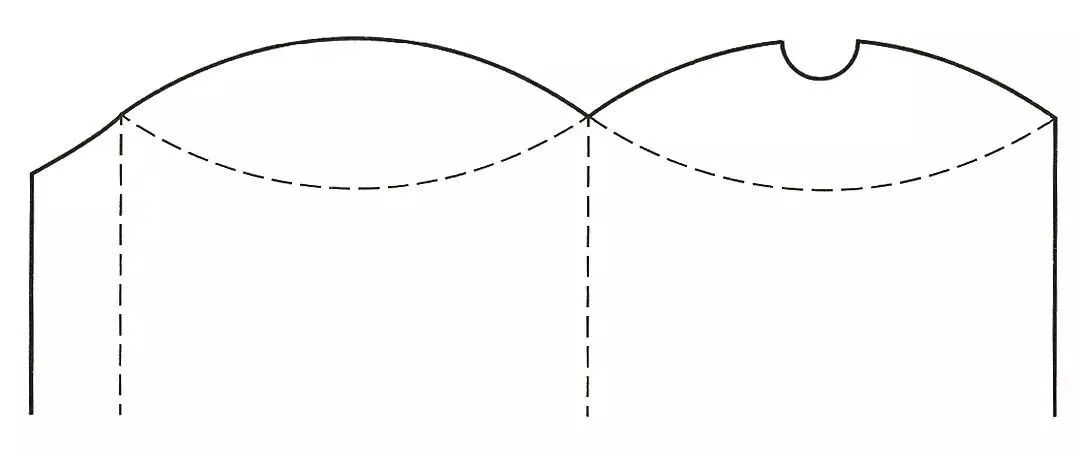

Unfolded diagram of the structure of the continuous swing-wing nest type box cover

Post time: Jul-12-2023