2. Bottom structure of tubular packaging boxes

The bottom of the box bears the weight of the product, therefore emphasizing firmness. In addition, when filling goods, whether it is machine filling or manual filling, simple structure and convenient assembly are the basic requirements. There are several main methods for the bottom of tube packaging boxes.

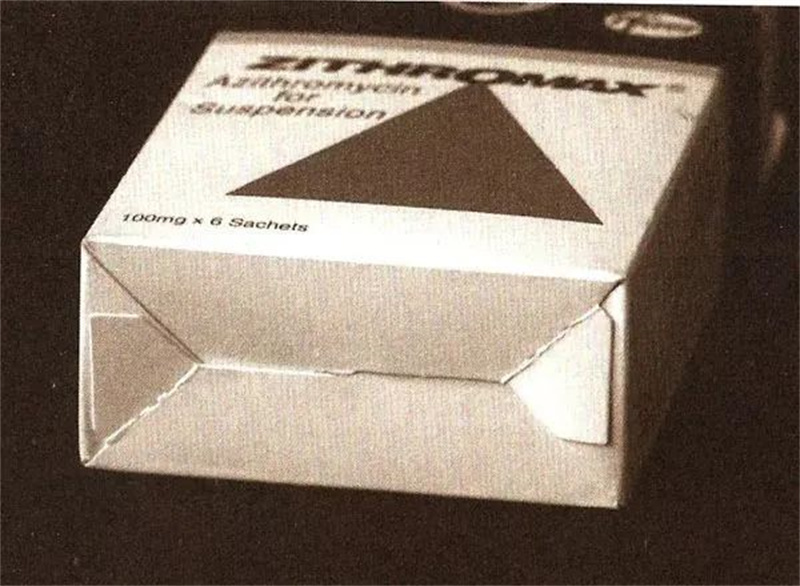

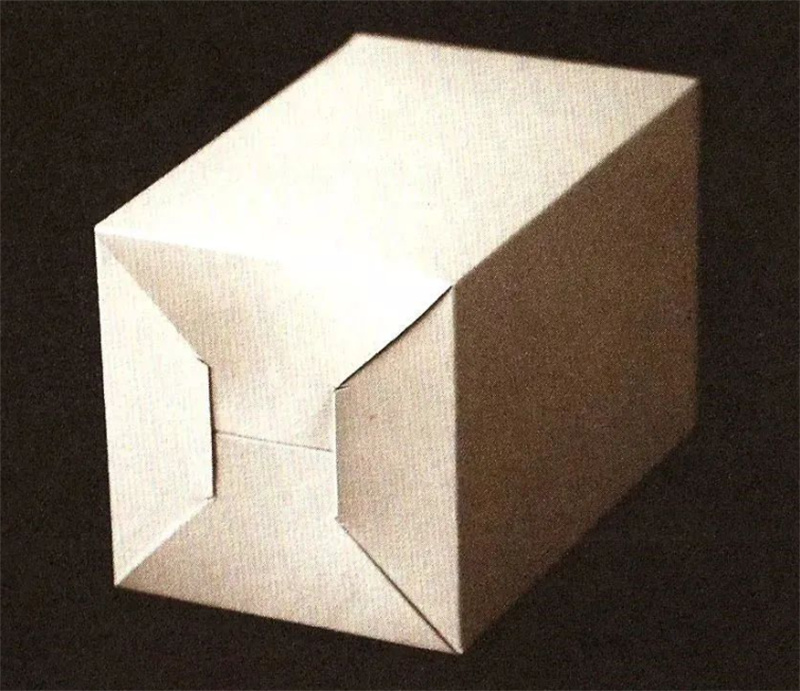

Non plug-in self-locking bottom

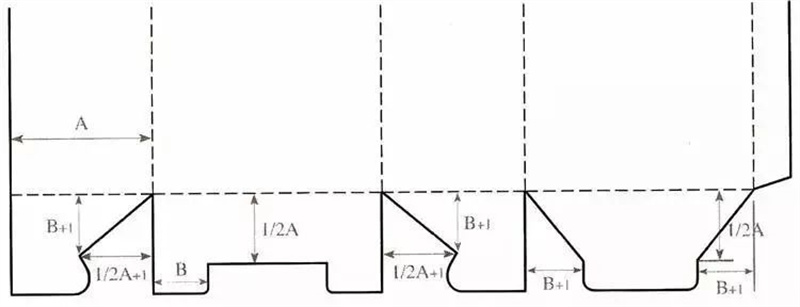

Utilize the four wing sections at the bottom of the tube packaging box to create a biting relationship with each other through design. This type of bite is completed through two steps: “separate” and “insert”, which is easy to assemble and has a certain load-bearing capacity. It is widely used in tubular packaging boxes.

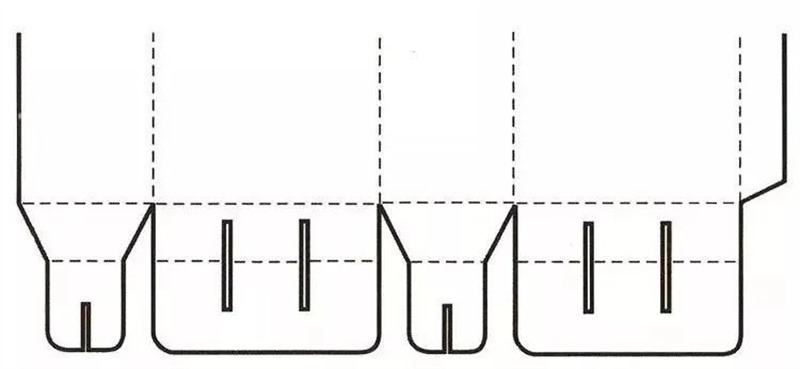

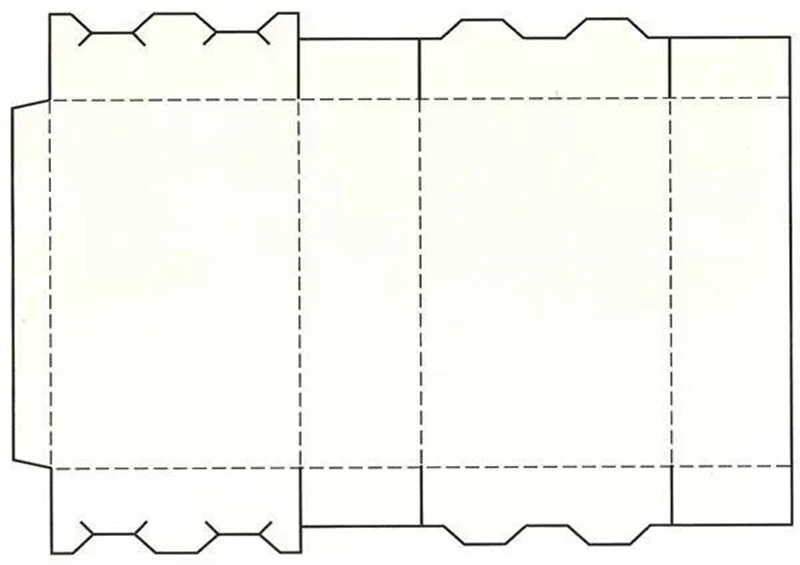

Expansion diagram of plug-in self-locking bottom structure

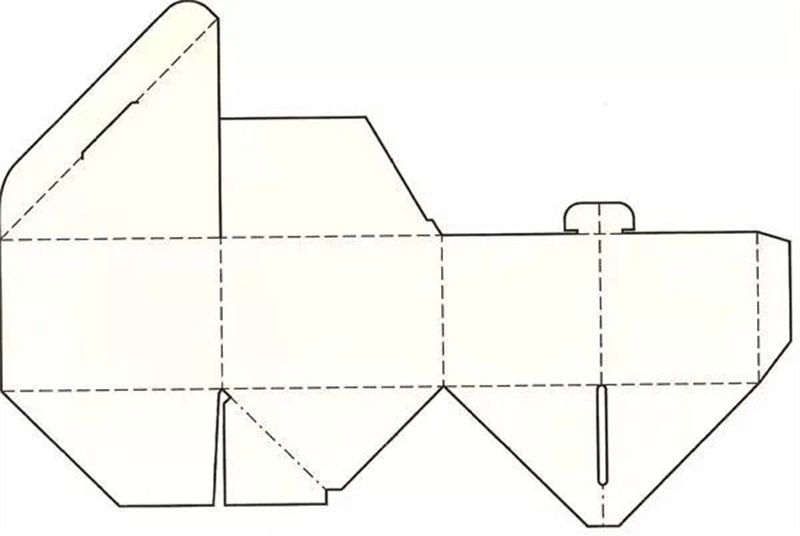

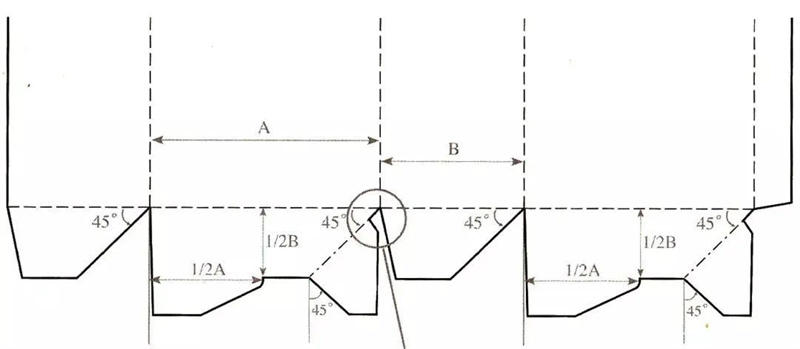

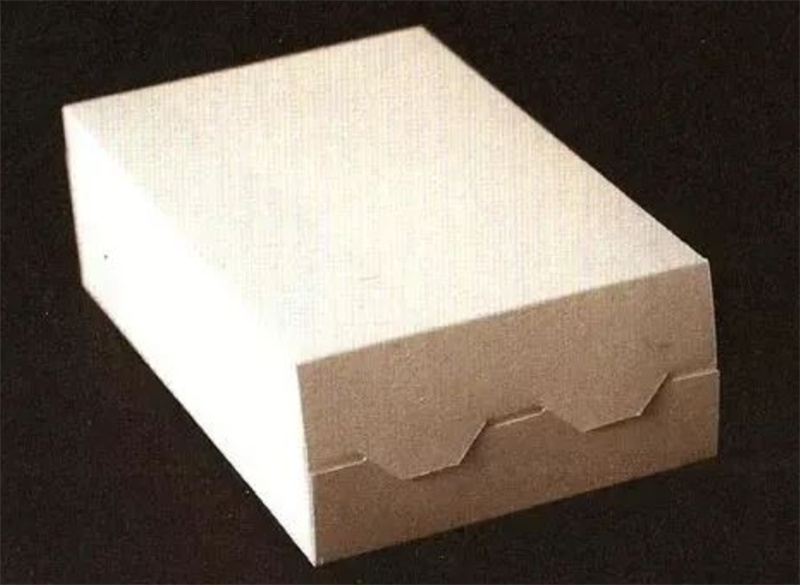

Automatic bottom locking

The automatic bottom locking packaging box adopts a pre adhesive processing method, but it can still be flattened after bonding. When used, as long as the box body is opened, the bottom of the box will automatically return to the locked state. It is extremely convenient to use, time-saving and labor-saving, and has good load-bearing capacity, suitable for automated production. Generally, this design structure is used for packaging designs that carry high weight items.

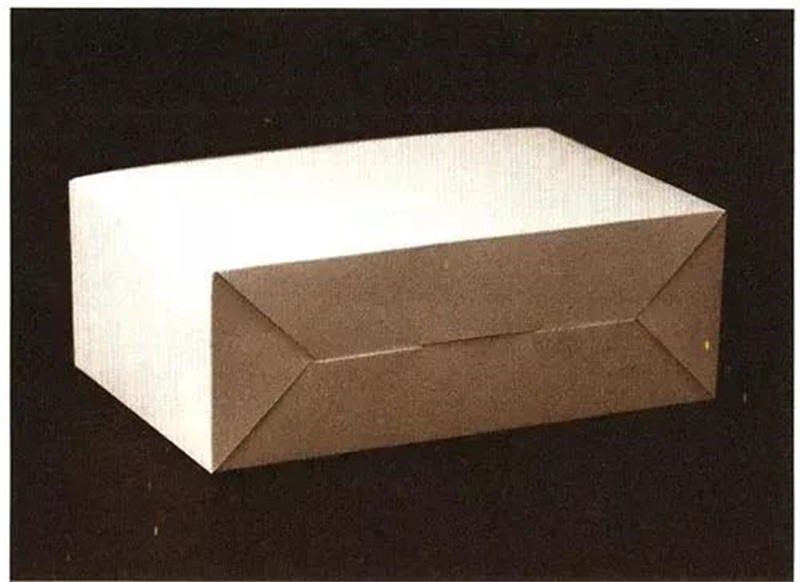

Expansion diagram of automatic bottom locking structure

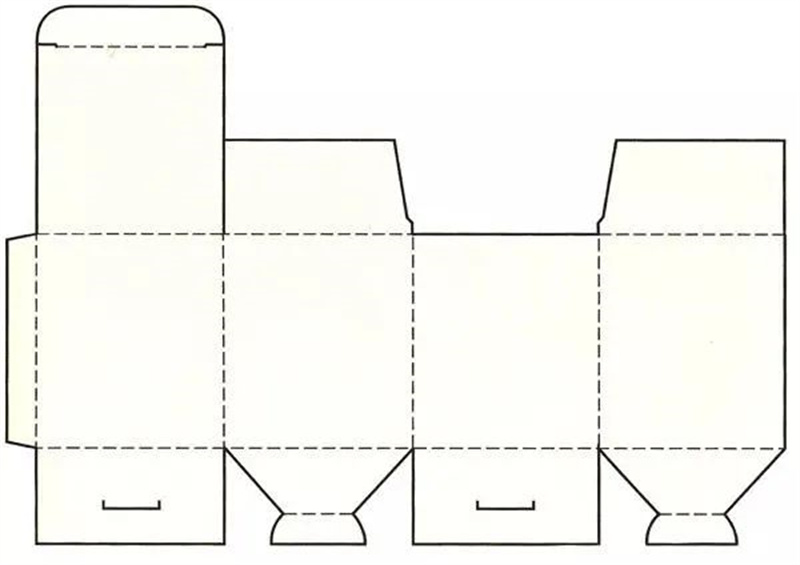

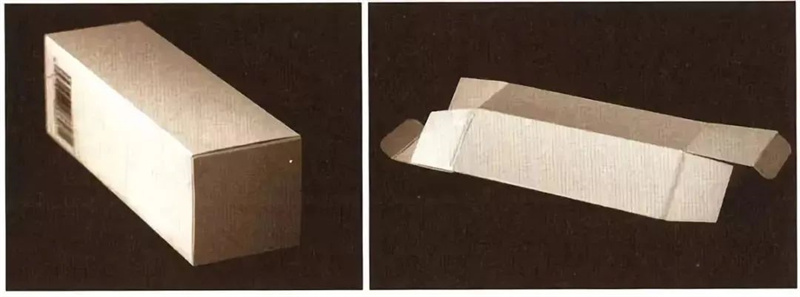

Shake cover double socket back cover

The structure is completely the same as the plug-in box cover with a swing cover. This design structure is simple to use, but has weak load-bearing capacity, and is usually suitable for packaging small or lightweight goods such as food, stationery, toothpaste, etc. It is the most common packaging box design structure.

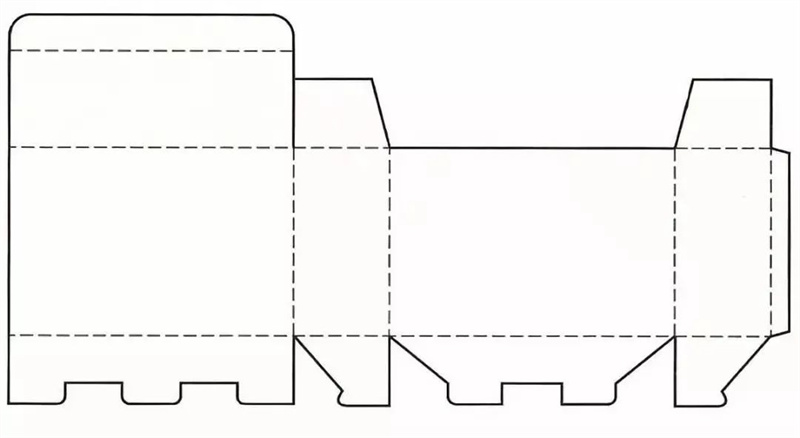

Unfolded diagram of the double socket bottom cover structure with a swing cover

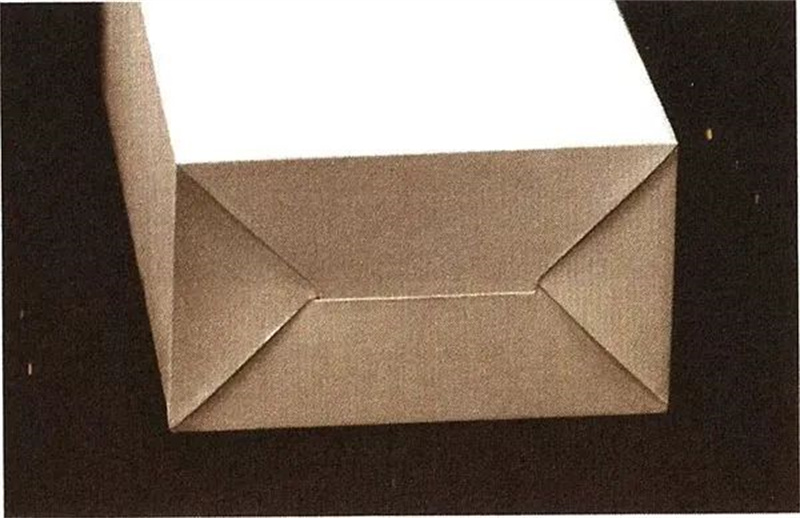

Wall sealing type

The partition bottom sealing structure is a structure that designs the four swing wings of a tubular packaging box into a partition function. After assembly, a partition will be formed inside the box body, effectively separating and fixing goods, providing good protection. The wall and box body are integrated, which can effectively save costs, and this packaging box structure has high compressive strength.

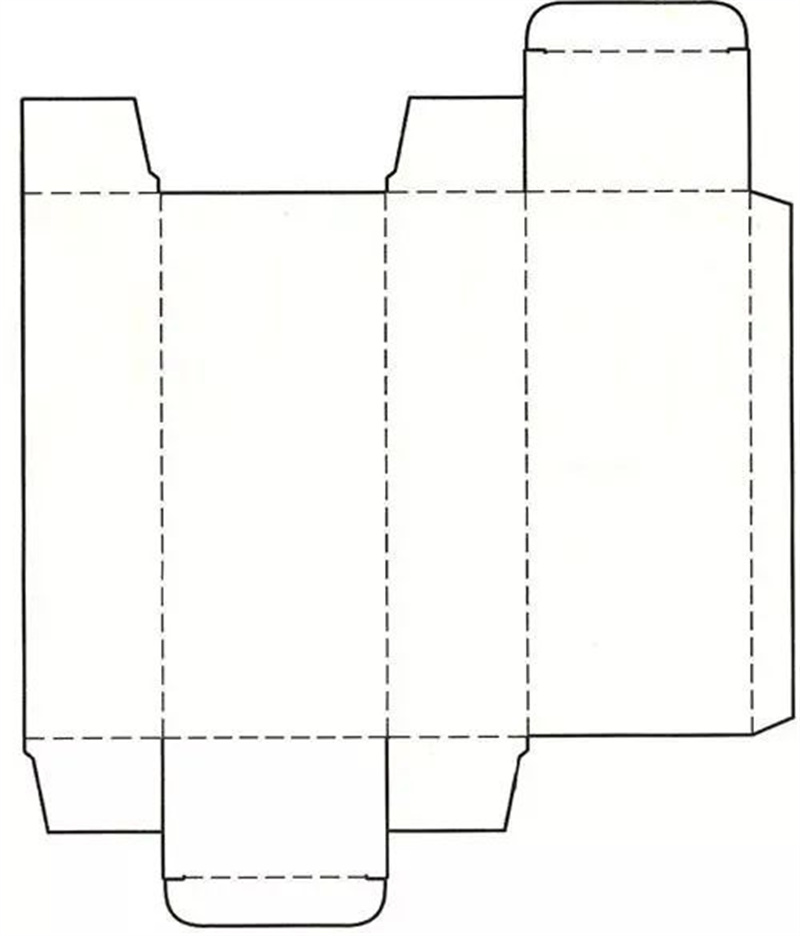

Other evolutionary structures

Based on the commonly used basic packaging box structural models mentioned above, other structural forms can also be evolved through design.

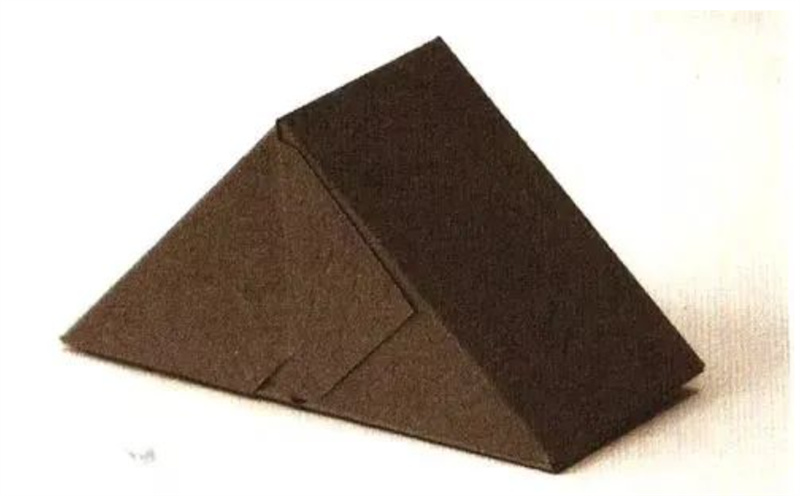

Expansion diagram of plug-in structure

Expansion diagram of plug-in structure

Expansion diagram of plug-in lock structure

Unfolded diagram of buckle type structure

Post time: Aug-09-2023